Category

Conveyor Belt Roller Design Rubber Lagging Ceramic Lagging Sheet

Conveyor Belt Roller Design Rubber Lagging ceramic lagging sheetWhy Choose Us: 1. Manufacturer with rich experience, goo

Basic Info

| Model NO. | DB-TC |

| Width | 500mm |

| Rubber Lagging | Available. |

| Our Advantage | Manufacturer,Direct Seal |

| Cn Bonding Layer | with a Cn Bonding Layer. |

| Length of Ceramic Lagging | in Pieces or in 10m Rolls |

| Lead Time | 7 Days. |

| Certification | ISO9001, ISO14001, ISO45001 |

| Custom Size | Available |

| Installation | Cond Bonding |

| Transport Package | Crate or Pallet |

| Specification | It depends on quantity and size of ceramic lagging |

| Trademark | JZDT |

| Origin | Jiaozuo, Henan, China |

| HS Code | 4008210000 |

| Production Capacity | 200, 000 Meters/Year |

Product Description

Conveyor Belt Roller Design Rubber Lagging ceramic lagging sheetWhy Choose Us:1. Manufacturer with rich experience, good quality.

2. Strong research and development capability.

3. Strict QC management.

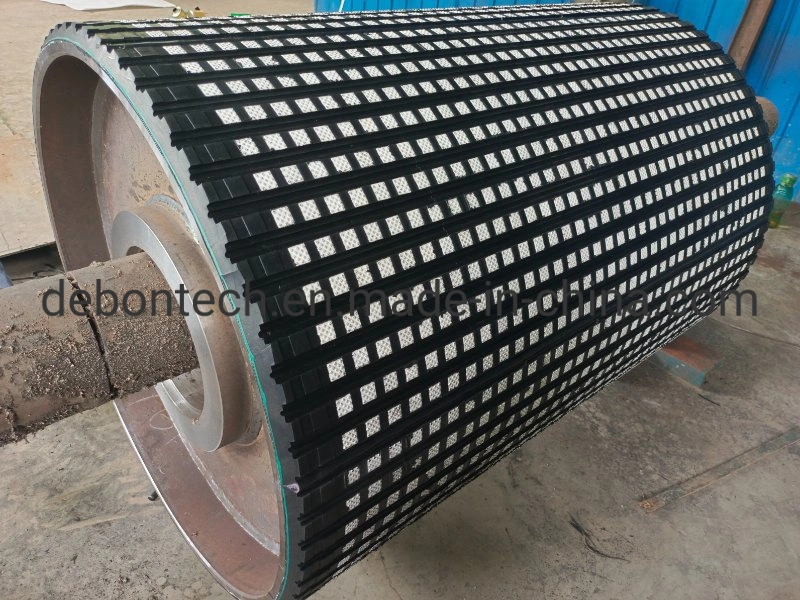

Diamond rubber lagging sheets for conveyor pulley lagging.

CN layer backed rubber ceramic lagging sheets.

Description of rubber backed ceramic pulley lagging:

Coefficient of friction between conveyor belt and pulley is a very important factor in determining the performance of a conveyor belt on a drive.Low coefficient of friction may cause conveyor belt slippage and lead to more wear of the belt and belt tracking problem. Rubber pulley lagging can reduce slippage and extend service life of conveyor belt.

Ceramic pulley lagging is high wear resistant pulley lagging material, the high alumina tiles increase the wear resistance and friction coefficient. The diamond nibbles considerably improve the belt grip and the wear life of the lagging material.

Ceramic lagging is an optimal solution for conveyor pulleys in tough applications.

Pulley ceramic lagging sheet can be produced with a cn bonding layer. CN layer helps offer fast and higher bonding strength.

Mining conveyor head pulley with ceramic lagging.

We also provide lagging service on site or at pulley factory.

Technical Data of Ceramic Lagging:

Ceramic Tile:

1. Al2O3: 95%

2. Ceramic Hardness(Mohs): > 9t

3. Working temperature: -40 - 85ºC

Rubber:

1. Material: NR & SBR

2. Hardness: 65 ± 5 Shore A

3. Density: 1.15 ± 0.05 g/cm3

4. Tensile strength: 18 MPa

5. Elongation at Break: 550%

6. Wear loss: <=100mm3

We also produce pulley lagging rubber sheets.

About Us:

Jiaozuo Debon Technology is a factory dedicated to the production, development and application of wear liners for mining facilities since 2001. The company has advanced production lines and testing apparatuses for rubber, polyurethane and ceramic and can provide wear solutions for various requirements for wear protection by using different wear-resistant materials.Main products include:pulley lagging, impact bed, conveyor belt cleaner, conveyor skirting, ceramic rubber composite liner, conveyor belt repairmaterials, etc. We could develop and produce different wear-resistant products according to customer requirements.Our products are widely exported to the UK, France, the United States, Australia, Russia, Kazakhstan, Southeast Asia and other countries and regions, and we also have large market shares and good reputations in China. Over the years, we have been winning good feedback from customers with high quality and consistency.

Main products:

1. Rubber ceramic lagging

2. Diamond rubber lagging

3. Plain rubber lagging

4. Replaceable rubber lagging

5. Conveyor belt cleaners

6. Conveyor skirt board

7. Impact bar and impact bed.

8. Wear liners

More information ,welcome to contact Mona Cheung.