Category

High Torque Cam Clutch BS 200 Back Stop Clutch Bearing for Belt Conveyor

Description of High Torque Cam Clutch BS 200 Back Stop Clutch Bearing for Belt Conveyor Introduction of High Torque Cam

Basic Info

| Model NO. | BS200 |

| Model | BS200 |

| Seals Type | Sealed |

| Precision | P6 |

| OEM | Accept |

| Stock | Rich |

| Package | Single Box or as Your Requirements |

| Delivery | 10-15days |

| Place of Origin | Changzhou China(Mainland) |

| Market | Global |

| Transport Package | Industry Packing |

| Specification | P0 |

| Trademark | SUMA or OEM |

| Origin | Changzhou, Jiangsu, China |

| HS Code | 84836000 |

| Production Capacity | 1000PCS/Yar |

Product Description

Description of High Torque Cam Clutch BS 200 Back Stop Clutch Bearing for Belt Conveyor

| Model | BS200 |

| Material | GCr15 |

| Inner diameter | 100-200mm |

| Outer diameter | 430mm |

| Thickness | 145mm |

| Torque capacity | 37200Nm |

| Overrunning speed | 100r/min |

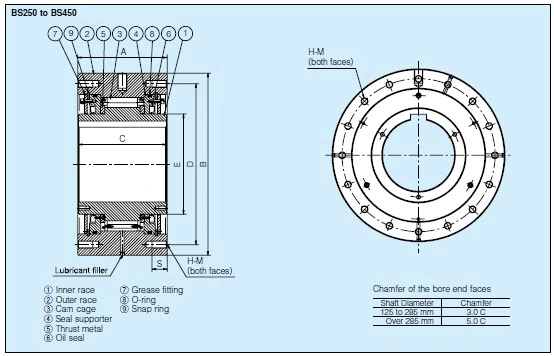

Introduction of High Torque Cam Clutch BS 200 Back Stop Clutch Bearing for Belt Conveyor

The BS series Cam Clutches are intended for applications where reverse rotation of the slow speed conveyor head shaft is to prevented (backstopping).

Parameter of High Torque Cam Clutch BS 200 Back Stop Clutch Bearing for Belt Conveyor

MODELS BS30 TO BS135

| Model | Torque Capacity (N·m) | Max. Overrunning (r/min) Inner Race | Drag Torque (N·m) | A | B | C | PCD D | E | S | H-M Size× Pitch × No.of Tapped HoleS | Grease Filler Hole (Size) | Q'ty Grease (kg) | Weight (Kg) |

| BS30 | 294 | 350 | 0.58 | 64 | 90 | 64 | 80 | 45 | 13 | M6 ×P1.0×4 | - | - | 21 |

| BS50 | 784 | 300 | 0.98 | 67 | 125 | 67 | 110 | 70 | 16 | M8 ×P1.25×4 | - | - | 4.0 |

| BS65 | 1570 | 340 | 3.92 | 90 | 160 | 85 | 140 | 90 | 20 | M10 ×P1.5×6 | - | - | 11.5 |

| BS75 | 2450 | 300 | 5.88 | 90 | 170 | 85 | 150 | 100 | 20 | M10 ×P1.5×6 | - | - | 13.1 |

| BS85 | 5880 | 300 | 7.84 | 115 | 210 | 110 | 185 | 115 | 30 | M12 ×P1.75×6 | - | - | 24.7 |

| BS95 | 7840 | 250 | 9.8 | 115 | 230 | 110 | 200 | 130 | 30 | M14 ×P2.0×6 | - | - | 29.4 |

| BS110 | 10800 | 250 | 14.7 | 115 | 270 | 110 | 220 | 150 | 30 | M16 ×P2.0×6 | - | - | 34.2 |

| BS135 | 15700 | 200 | 19.6 | 135 | 320 | 130 | 280 | 180 | 30 | M16 ×P2.0×8 | - | - | 68 |

MODELS BS160 TO BS450

Model | Torque Capacity (N·m) | Max. Overrunning (r/min) Inner Race | Drag Torque (N·m) | A | B | C | PCD D | E | S | H-M Size× Pitch × No.of Tapped Holes | Grease Filler Hole (Size) | Q'ty of Grease (kg) | Bore Diameter Range (mm) | W. Max kg | W. Min kg |

| BS160 | 24,500 | 100 | 33.1 | 130 | 360 | 130 | 315 | 220 | 40 | M20 × P2.5 ×10 | PT 1/4 | 0.12 | 100 to 160 | 98.1 | 85.6 |

| BS200 | 37,200 | 100 | 44.1 | 150 | 430 | 145 | 380 | 265 | 40 | M22 × P2.5 × 8 | PT 1/4 | 0.14 | 100 to 200 | 167 | 140 |

| BS220 | 49,000 | 80 | 73.5 | 235 | 500 | 230 | 420 | 290 | 40 | M20 × P2.5 ×16 | PT 1/4 | 0.8 | 150 to 220 | 301 | 264 |

| BS250 | 88,200 | 50 | 93.1 | 295 | 600 | 290 | 530 | 330 | 50 | M24 × P3.0 ×16 | PT 1/4 | 1.1 | 175 to 250 | 580 | 523 |

| BS270 | 123,000 | 50 | 98 | 295 | 650 | 290 | 575 | 370 | 50 | M24 × P3.0 ×16 | PT 1/4 | 1.2 | 200 to 270 | 620 | 562 |

| BS300 | 176,000 | 50 | 108 | 295 | 780 | 290 | 690 | 470 | 60 | M30 × P3.5 ×16 | PT 1/4 | 1.3 | 230 to 300 | 952 | 885 |

| BS335 | 265,000 | 50 | 137 | 305 | 850 | 320 | 750 | 495 | 70 | M36 × P4.0 ×16 | PT 1/4 | 1.4 | 250 to 335 | 1,140 | 1,040 |

| BS350 | 314,000 | 50 | 157 | 320 | 930 | 360 | 815 | 535 | 70 | M36 × P4.0×16 | PT 1/4 | 1.5 | 250 to 350 | 1,600 | 1,470 |

| BS425 | 510,000 | 50 | 216 | 440 | 1,030 | 450 | 940 | 635 | 70 | M36 ×P4.0 ×18 | - | Oil 6,000ml | 325 to 425 | 2,450 | 2,240 |

| BS450 | 686,000 | 50 | 245 | 450 | 1,090 | 480 | 990 | 645 | 80 | M42 × P4.5 ×18 | - | Oil 7,000ml | 350 to 450 | 2,820 | 2,580 |

W. Max Weight at Maximum Bore