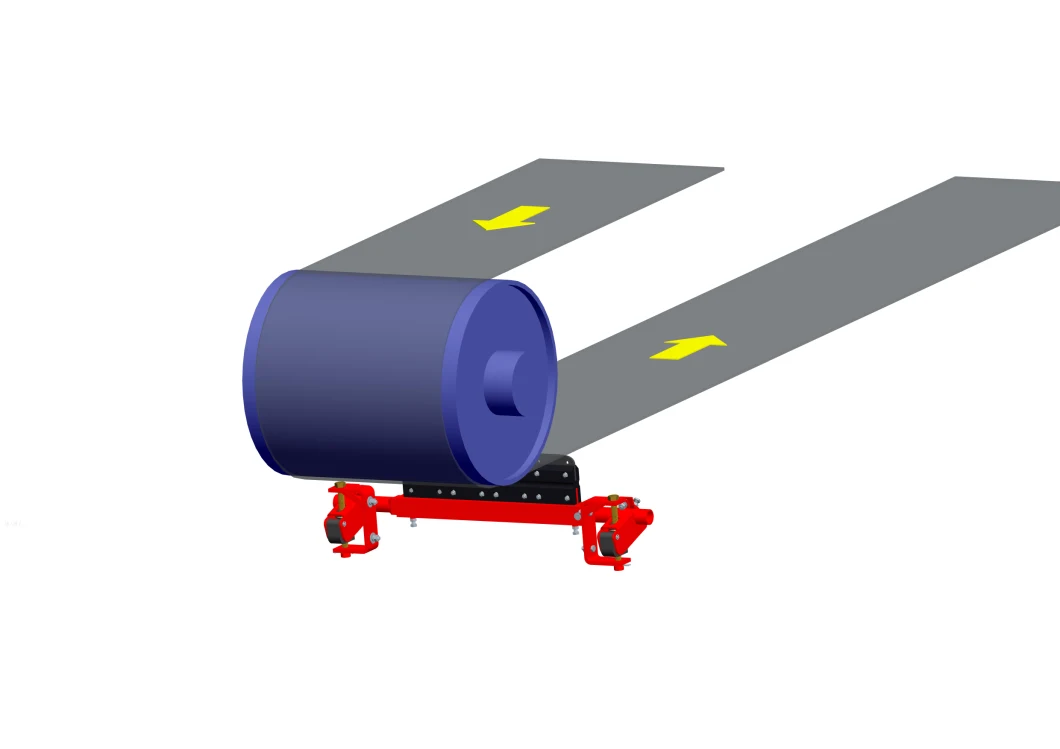

Secondary Belt Cleaner for Conveyor Alloy Cleaner

Basic Info

| Model NO. | SP02-P1 |

| Material | Tungsten Carbide Alloy |

| Tensioner | Spring Tensioner |

| Transport Package | Plywood Case |

| Specification | 650-2400 |

| Trademark | SZS |

| Origin | Nanjing, China |

| HS Code | 7326 |

| Production Capacity | 1000sets/Month |

Product Description

Product introduction

SZS secondary cleaners are installed at the point where the belt leaves the discharge pulley to remove any residual amounts of material that the primary cleaner left on the belt. Like the SZS primary belt cleaners, these products are highly durable and efficient.Typically, a secondary cleaner is installed against a roller close enough to the primary cleaner that the material is returned to the main material stream. Additional secondary cleaners can be added for final cleaning.

Compact secondary belt cleaner design allows installation in close quarters; narrow profile resists material buildup Rubber buffers allow for reversal of belt direction without damage to belt.

Product Description

| Belt Width | up to 2400 mm |

| Belt Speed | Up to 6.1 m/s |

| Temperature | Between -30 degrees F and 300 degrees F |

| Corrosive Conditions | Yes |

| Underground Applications | Yes |

| Compatible with Reversing Belts or Roll Back | Yes |

| Accommodates Mechanical Splices | Yes |

Detailed Photos

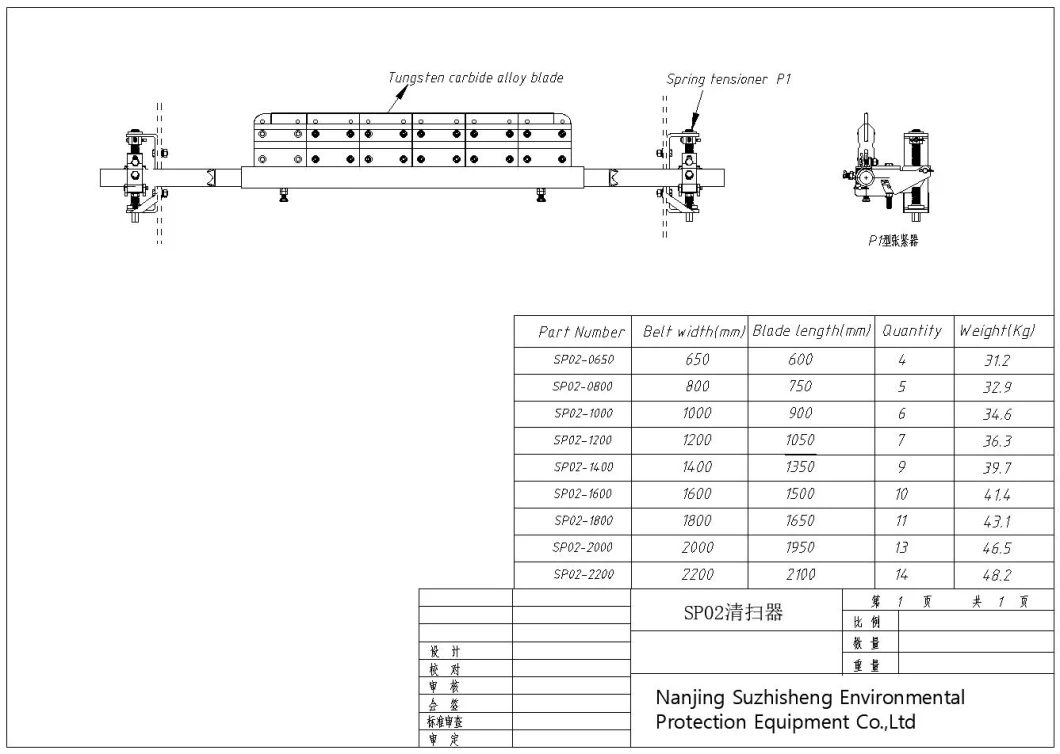

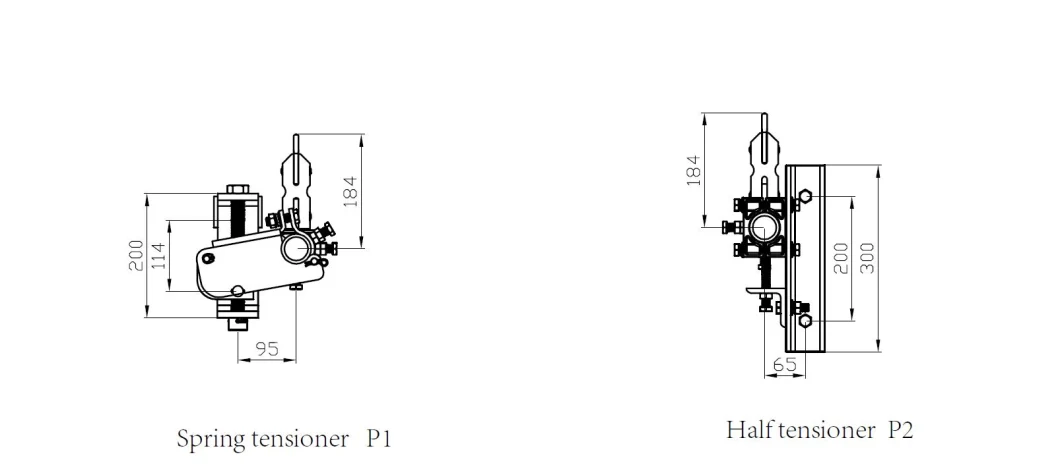

Product-related drawings

Company Profile