Trx SS304 Powered Conveyor Logistic Sorting Conveyor Roller

Basic Info

| Model NO. | TRX-SS |

| Certification | ISO&SGS |

| Pipe Thickness | 1.0/1.5/2.5/3.2(mm) |

| Condition | New |

| Warranty of Core Components | 12 Months |

| Dimension(L*W*H) | Variable |

| Usage | Conveyor Belt System |

| Application Industry | Logistics,Transportation |

| Color | Silver |

| Shaft | S/S304 |

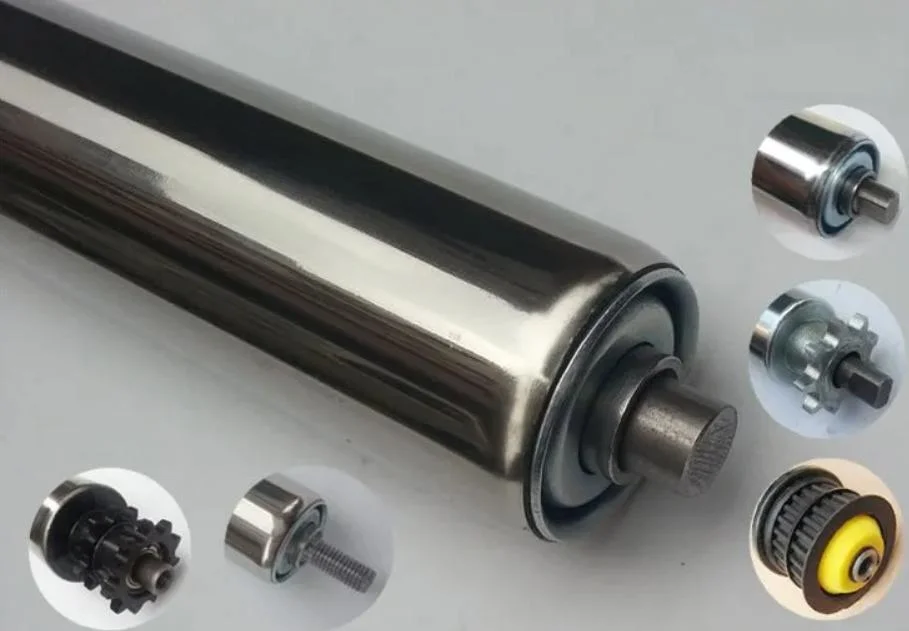

| Installation Way | Spring Load, Female Thread, Outside Thread, Mortis |

| Bearing | with& Without |

| Transport Package | Wooden Case |

| Specification | Roller Length 190-2000mm |

| Trademark | TRX |

| Origin | China |

| HS Code | 8431390000 |

| Production Capacity | 30000 PCS/Month |

Product Description

TRX SS304 Powered Conveyor Logistic Sorting Conveyor RollerProduct Description

Stainless steel rollers are available for a wide array of applications that require corrosion resistance, wash down, and caustic environments.

The rollers may be all stainless or may be manufactured in options such as just the tube, just the bearing or axle, or any combination depending on the severity of the application.

304-grade stainless steel is the standard stainless material offered.

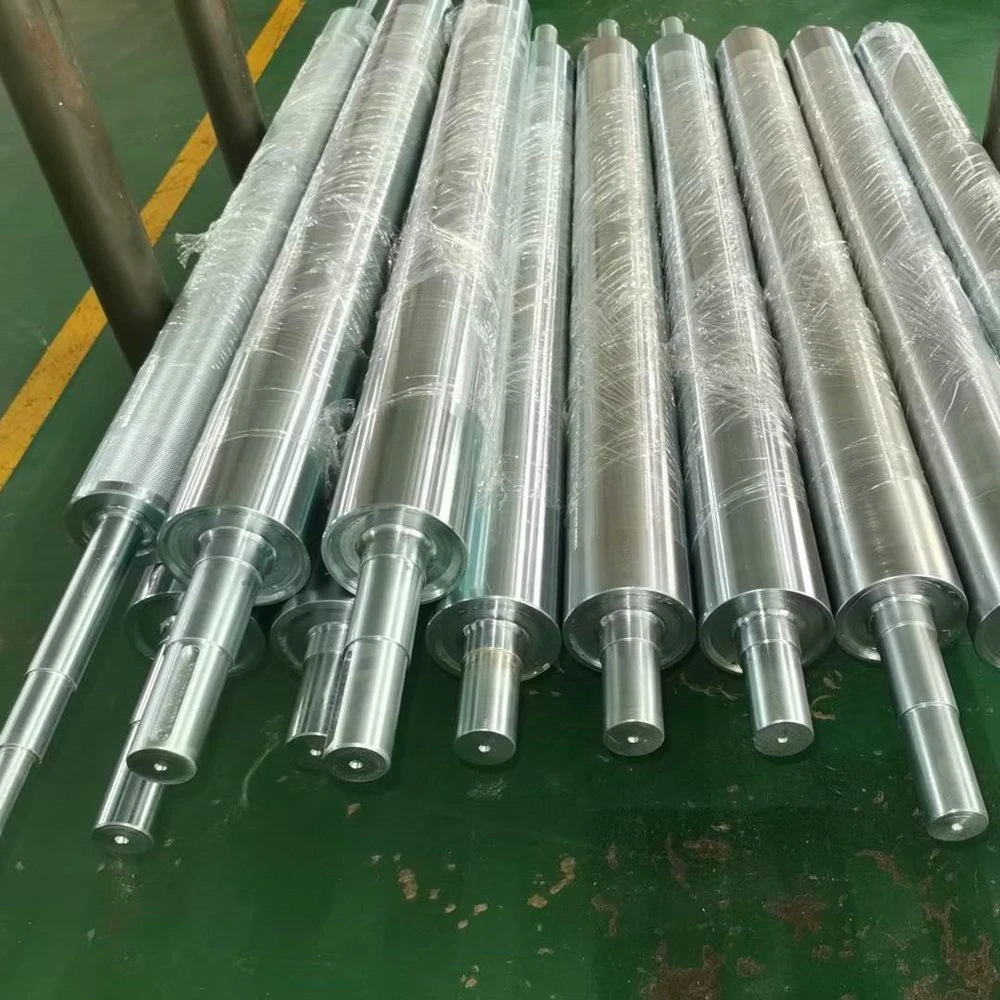

Detailed Photos

Details for stainless conveyor idler feature:

1.Roller idlers Dia 60mm-159mm, length 190-2000mm, which are used in the corrosion environment such as marine site, chemical industry, acid and alkaline environment, humid and wet environment etc

2.Tube: S/S304

3.Shaft: S/S304

5.Bearing: Single & Double Row Deep Groove Ball Bearing 2RZ&2Z with C3 clearance.

6.Seals: Grease retaining inner seal with Multi-stage Labyrinth and Retention Cap with Outboard Rubbing Flinger Seal.

7. Lubrication: Grease is Lithium soap type grease with Rust Inhibitors.

8. Welding: Mixed gas shielded arc welding end

9. Painting: ordinary painting, hot galvanized painting, electric static spraying painting, baked painting

Besides we can manufacture the rollers and idlers according to the buyers' requirements.

Roller diameter | Thickness mm | Shaft diameter | Roller length mm | Tube material | Shaft material | Roller surface treatment | Installation |

Φ16 | 1.0 | Φ6,Φ8 | 80-400 | PVC | Steel, stainless steel | ||

Φ20 | 1.0 | Φ6, Φ8 | 80-400 | PVC | Steel, stainless steel | Galvanized, chrome plated, sand spraying, rubber coated, | Spring load, mortise, punch |

Φ25 | 1,1.2 | Φ8 | 80-500 | PVC, steel, stainless steel | Steel, stainless steel | ||

Φ30 | 2.0 | Φ8 | 80-500 | PVC | Steel, stainless steel | ||

Φ38 | 1.2, 1.5, 2.0, 3.0 | Φ12,Φ15,Φ20 | 80-3000 | PVC, steel, stainless steel, aluminum alloy | Steel, stainless steel | ||

Φ40 | 2.5 | Φ8 | 80-600 | PVC | Steel, stainless steel | ||

Φ42 | 1.2, 1.5 | Φ12, Φ15 | 80-3000 | steel | Steel, stainless steel | ||

Φ50 | 1.2, 1.5, 2.0, 2.5, 3.0 | hex11, Φ12,Φ15, Φ20,Φ25 | 80-3000 | PVC, steel, stainless steel, aluminum alloy | Steel, stainless steel | ||

Φ60 | 1.5, 2.0, 2.5, 3.0 | hex11, Φ12,Φ15,Φ20, Φ25,Φ30 | 80-3000 | PVC, steel, stainless steel, aluminum alloy | Steel, stainless steel | ||

Φ63.5 | 2.0, 2.5,3.0 | hex17, Φ12, Φ15 | 80-2000 | Steel | Steel, stainless steel | ||

Φ76 | 2.0,2.5,3.0, 4.0, 5.0 | Φ12,Φ15,Φ20, Φ25,Φ30,Φ35 | 80-3000 | Steel, stainless steel, aluminum alloy | Steel, stainless steel | ||

Φ89 | 2.5, 3.0, 3.5, 4.0, 5.0 | Φ20, Φ25,Φ30, Φ35,Φ40 | 80-3000 | Steel, aluminum alloy | Steel, stainless steel | ||

| |||||||

| Name | Light Gravity roller | Model | TRX |

| Length(mm) | OEM | Overal width(mm) | 540MM |

| Width(mm) | N/M | Hieght (mm) | N/M |

| Material | Galvanized steel | Color | Galvanize color |

| Motor power | N/M | Speed | N/M |

| Load capacity | 50KGS/M | Roller/belt/chain type | O groove or gravity |

| Warranty | 12 months | OEM | Yes |

Company Profile

Hebei TRX Rubber Products is a leading professional manufacturer of conveyor belts & conveyor accessories in China. The main workshops cover 20,000 square meters in the total 60,000 square meters of the plant. The applied technology and equipment in the advanced production lines are state of the art in the industry. The sales headquarters is located in the capital of China, Beijing with branches in domestic and abroad.

It specializes in following three series: 1) Heavy-duty Conveyor Belt, including universal EP/NN and CC Belt, Chevron Belt, Oil Resistant Belt, Abrasion Resistant Belt, Heat Resistant Belt, Fire Resistant Belt, Chemical Resistant Belt, Sidewall Belt, Flat Transmission Belts, 2) Rubber Sheets, including SBR, NBR, NR, CR, EDPM, Rubber With Insertion 3) Conveyor accessories. These three series of products conform to RMA, DIN, ASTM and ISO specifications.

Its products, honored with "The most Advanced level of Products" by the Committee of Science and Technology, have been widely used in mining and quarrying, power stations, steel plants, bulk cargo terminals, cement industry, and other material handling fields. With great success in domestic market, it has been focusing on global market with several hundreds of foreign valued customers in Asia, South America, North America, Africa and Europe.

The company mission:

2. Engage in complete solutions with conveyor belting and power transmission belting.

3. Persist in technology improvement and quality control in the whole process of production and service.